VIP - Vacuum Insulating

Panel

The Best Building Insulation Material on the Market

A super insulation material reaching R-30 per inch of thickness.

What is VIP?

Vacuum Insulating Panel (VIP) is a relatively new type of super insulation combining vacuum insulation technology and microporous insulation technology. The VIP consists of a porous nano-core material sealed in vacuum with a high-performance gas barrier skin. This construction dramatically reduces thermal conduction, convection and radiation, making it more efficient in insulative performance than nearly any other material. The finished product appearance is rectangular and flat, the outer skin feels slightly elastic and has a certain toughness, available with various barrier materials depending upon the end application.

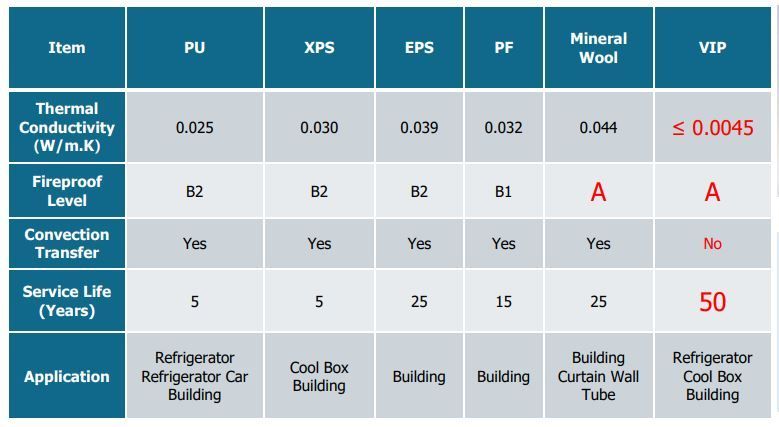

Compare VacuumGlass® VIP to other building insulating products

Thin and Efficient: VIPs feature the highest thermal performance of any insulation material on the market, with up to 10 times the insulation value of traditional materials like fiberglass or foam at R-30 per inch.

- VIPs have the highest thermal performance of any insulation material on the market, with up to 10 times the insulation value of traditional materials like fiberglass or foam.

- VIPs are incredibly thin, with thicknesses as low as 10mm, making them ideal for space constrained applications where traditional insulation would not be feasible.

- VIPs have a long service life, with typical lifetimes of up to 50 years or more, and require little to no maintenance.

- VIPs are environmentally friendly, with very low embodied energy and minimal carbon footprint compared to traditional insulation materials.

- VIPs are fire resistant, with some panels able to withstand temperatures up to 1,000°C for extended periods of time.

- VIPs can help reduce energy consumption and lower heating and cooling costs, making them an attractive option for environmentally conscious customers looking to save money.

Advantages of VIP

- VIPs are versatile and can be used in a wide range of applications, including building envelopes, refrigeration, transportation, and more.

- VIPs are lightweight and easy to handle, making them ideal for applications where weight is a concern, such as in aerospace or automotive applications.

- VIPs are non-toxic and do not contain any hazardous materials, making them safe for use in a variety of settings.

- VIPs are backed by extensive research and development, with ongoing innovation in the field leading to new and improved products with even better performance characteristics.